GLP real-life safety

Lithium-ion batteries are heavy, expensive and are sensitive to both temperature and humidity. Batteries need to be stored in a dedicated environment that’s purpose-built for the task.

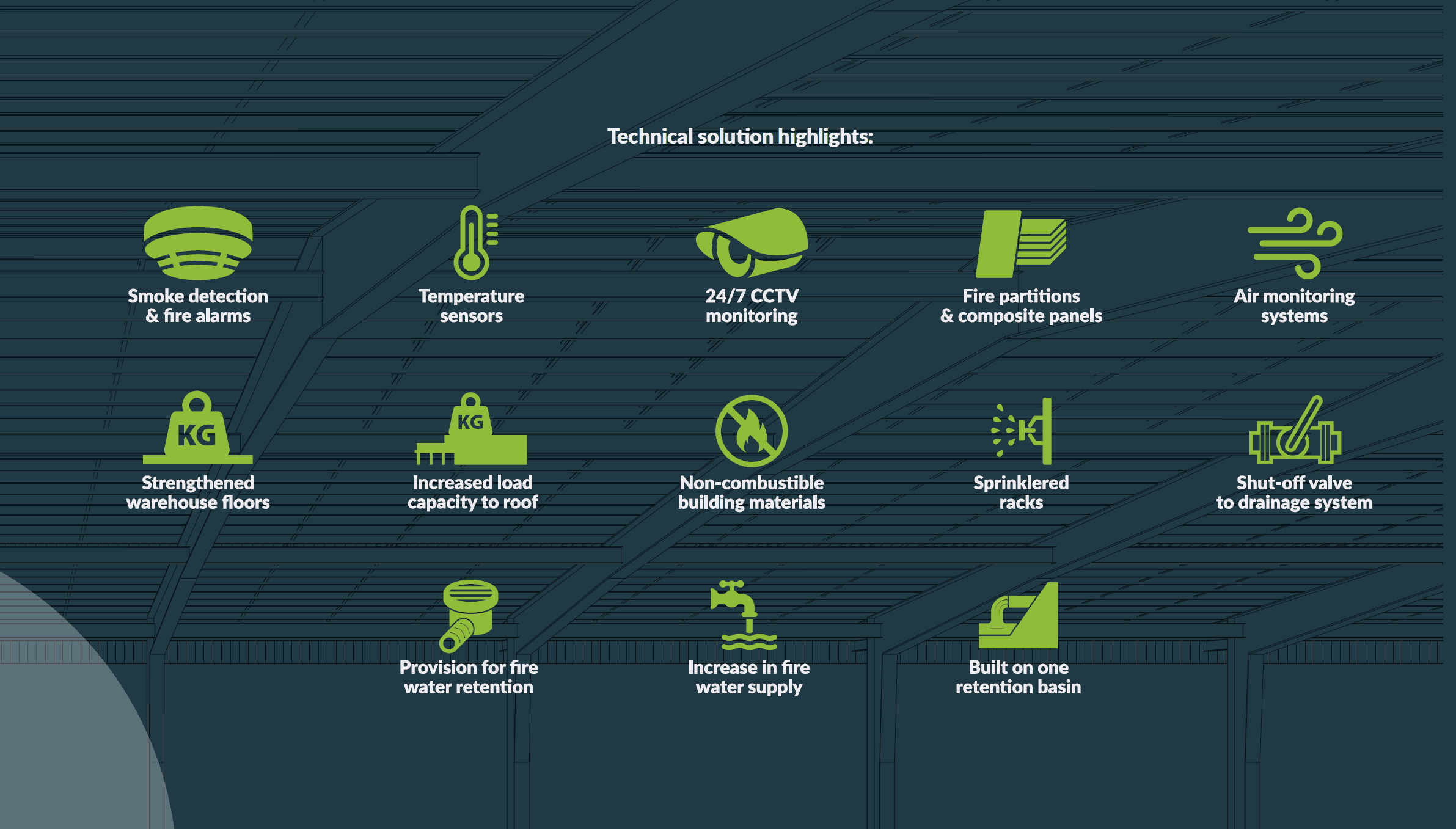

GLP is a global leader in logistics real estate with a long heritage and proven track record as a developer, operator and asset owner with one of the largest logistics footprints in the world. We understand how important it is to design safe and secure buildings, specifically to meet these demands and have experience in delivering these facilities across the world.