While the GLP name appeared on logistics buildings across CEE only in mid-2020, the company has already managed to make a strong presence in key markets. The key CEE market is Poland, where GLP develops new projects and introduces a brand new standard of speculative development.

“Our experience working with clients has shown that more and more of them expect solutions that, until recently, were mainly available mainly in built-to-suit (BTS) facilities. Given the market dynamics and increased demand for warehouse space amid the pandemic, we believe that this is a good time to set a new standard for speculative buildings.” says Jarosław Czechowicz, Country Manager, GLP Poland.

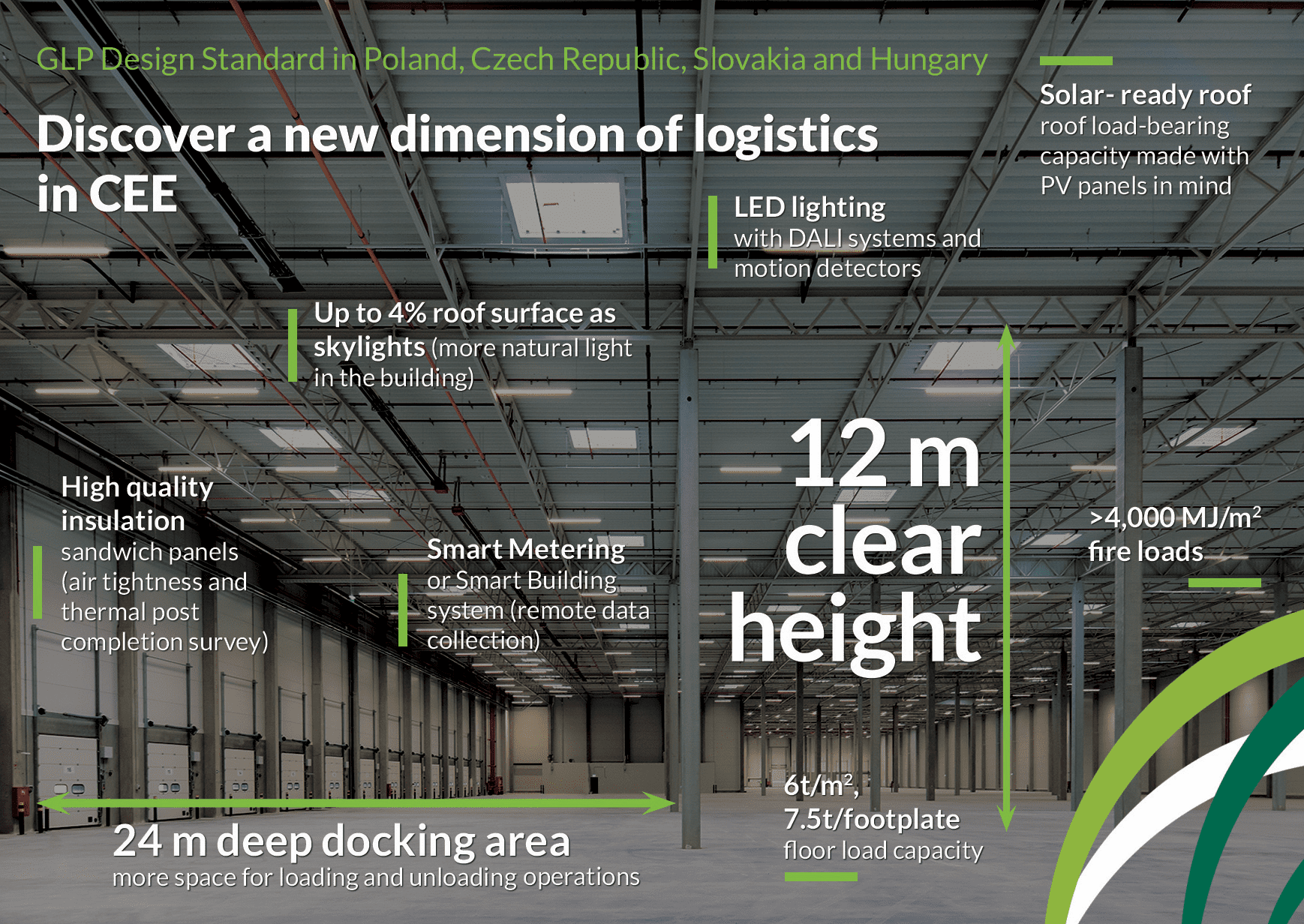

Key features of the GLP European Design Guide features, applied to the Polish market

Two metres make a difference

The main advantage of GLP buildings developed to the European Development Standard is the height, which is two metres higher than typical logistics buildings. With a clear height of twelve metres, customers are given an additional storage level in the warehouse, which can generate lease savings of up to 40%.

More light and space

With a reinforced structure allowing for a larger loading area up to 24 metres wide, the movement of forklifts is made easier, supporting the entire handling process. Better working conditions are also enabled through twice the usual number of skylights, with 4 SQ M of skylight area per 100 SQ M of roof area.

Renewable Energy – Solar PV

To date, GLP buildings worldwide have been fitted with over 1.5 million SQ M worth of solar panels, which have generated a total of 86 megawatts of energy. Through reinforced roof structures, buildings developed in Poland will now allow clients to install solar panels, enabling energy to be derived from renewable sources.

Control over utility consumption

New GLP buildings in Poland will be fitted with smart metering systems as standard. This will allow customers to monitor and control energy usage more effectively.

The use of LED lighting with DALI smart control ensures lower energy consumption. In addition, before being handed over to the customer, GLP buildings are scanned with a thermal camera for any missing insulation and thermal bridges.

All new GLP buildings in Poland will be rated “Very Good” or “Excellent” against the BREEAM certification scheme.

Christophe Brzezinski, Head of Technical Development, GLP Poland, said, “Better energy efficiency in our developments is one of GLP’s most important goals worldwide. Operating in a building that meets the highest standards in this regard is an opportunity for our customers to make long-term savings and achieve their own sustainability and environmental goals.”

Unusual needs as standard

The higher-specification buildings, while speculative, will be suitable for use by companies within a range of industries. For example, the standard involves the highest fire-resistance rating for buildings (MJ>4,000), which allows for the storage of flammable goods.

In addition, to accommodate manufacturing companies, the standard involves increased floor loading capacity to 7 t/m2, so that the floor can bear the load of heavy machines. The thickened floor also allows the use of VNA trucks with an inductive-loop detector system.

Health and wellbeing

GLP’s new developments will be equipped with cycling amenities for employees, such as covered bicycle stands, and the buildings will have green landscaped surroundings with dedicated nature parks. The office spaces will feature increased noise insulation – especially in production buildings with loud machinery – as well as more effective ventilation to reduce viral transmission.